What is Baobuche and what is its use?

What is Baobuche? And how is it made? | Features of Baobuche Pages | Applications of the Baobuche page

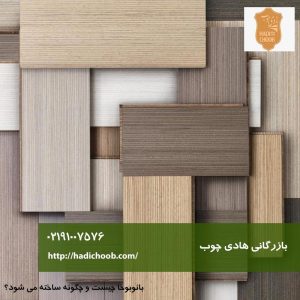

What is Baobuche? | Baobuche Pages | Baobuche Pages

Wood as a building material has recently experienced a favorable recovery. Its usability has been known as a raw material for a long time, but its importance due to a renewable resource has increased in recent years.

Today, softwoods are used exclusively in the manufacture of wood materials, which is why the processing of hardwoods as building materials is so complex and expensive.

Nowadays, a new method has been devised in which hardwoods of local forests are used to make durable and affordable plates.

One of these pages is called the Baobuche Pages. These plates are made of laminated and laminated wood that are either parallel or cross-linked.

Baobuche plates are a kind of multilayer plates, but unlike plywood, these plates use a layer parallelization method.

These plates are state-of-the-art and they are more affordable than other hardwood plates.

Wood used for makingBaobuche plates

Baobuche plates are produced more than hardwoods, and the technology used to build them is specific to these trees.

The most common and common wood for making Baobuche plates is beech wood. And the pages sold in Hadi Wood Trading are Baobuche Rush. Hadi Wood Trading also has the most varied sizes of Baobuche plates throughout Iran.

Advantages and Features of Baobuche Plates

It is affordable to build.

Baobukha plates can be used for a variety of applications, including interior design, furniture, and more.

These plates are made of natural wood and have no harm to the environment.

Baobukha plates can be manufactured in high dimensions and in different thicknesses.

Because of its parallel laminate structure, it has extraordinary natural beauty.

Has high resistance to pressure and heavy load.

Due to its high density and uniformity, it saves connections and makes it more economical to use than other pages.

Baobukha beech plates are robust and have high stability.

High diversity in page production

excellent quality

Allows the manufacturer to make slim plates with high strength.

It has very high flexural strength.

Baoha plates have a high screw and the screws and nails used do not slip.

These plates are resistant to all kinds of pests, including insects and fungi.

They are heat and cold insulated.

They have high flexural strength.

Application of Baobukha Pages

Baobukha wooden plates are used to make all kinds of wooden structures. The all-wood layered structure of these plates gives them high flexural strength and flexibility. As in most cases, these pages are preferred to multilayer pages.

Baobukha beech plates are mostly used as flooring and wall coverings.

Baobucha Flooring Due to its unique features, it can be installed in any location, including apartments, kindergartens, schools, museums, offices and public buildings, gymnasiums and more.

These pages have other uses.

Making all kinds of tables and chairs

Manufacture of wooden doors

Manufacture of books and bookshelves

Shells and boxes

interior design

decoration Furniture

Office Counters

Walls of wooden houses

Making pallets

Making cabinet plates

And all kinds of stairs

The steps of making Baobukha plates

The construction of Baobucha plates, like other wooden plates, is required in the following steps. We have also put together a complete video of making Baobukha pages for you.

Step One: Cut down trees and cut wood

Second step: Cutting the bark of tree trunks

At this point, the bark of the tree trunks is cut with special machines and the trunks are created uniformly.

Step Three: Laminate the trunks

The trunks of the trees are cut into thin layers with large pileers.

Step Four: Dry the sheets

The moisture content of the sheets is reduced after passing through the special machines and so-called dry sheets.

Step Five: Cut the sheets in certain dimensions

The sheets obtained from the previous step are cut into certain dimensions and create even layers.

Step 6: Iron the layers

Layers of the same size are ironed by special presses to create smooth, uniform plates.

Step Seven: Qualitative Review

The ironed layers are checked for quality and the layers that do not meet the required standards are excluded.

Step Eight: Gluing

Wood sheets are made with special glue machines (this is done in both spray and roller methods)

Step 9: Overlay the layers

The adhered layers are arranged in a certain number.

Step 10: Pressing

Layered layers are inserted into the press and transformed into uniform plates under certain pressure and heat.

The final step: pay and deduct

The edges of the plates are polished to give smooth surfaces.

They are then painted on laminated sheets or a variety of colors and lacquers upon customer request.

Video build Baobucha pages in stages from zero to one hundred

Price of Baobukha Pages

The price of Baobukha sheets varies with the thickness of the fabric. Hadi Wood Trading, a supplier of all types of boards and timber, has the best and lowest prices for you dear customers. Contact our consultants for pricing information